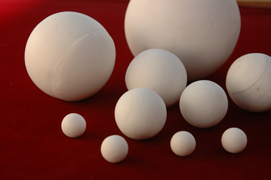

Steatite Balls

Steatite Grinding Media

Our steatite Grinding media have high density and more resistance to wear and corrosion, than natural stone. It has more resistance to abrasion compared to natural pebbles, porcelain grinding media. This steatite grinding media are more efficient & cost effective where fine grinding is very important process, just like in paints, ceramic, stains, ceramic glasses, Granite minerals and other industries.

Easy & quick grinding saves the electricity, the energy & time. Many factors like R.P.M. of Ball Mill, size & initial Raw materials, hardness of Raw materials, Ratio of Grinding Media to material & water, quality of Grinding Media & Lining Bricks – i.e. hardness, bulk density & abrasion loss, play an important roll in adequate grinding.

This steatite Grinding Media has ability to ground the material having hardness, up to 7 moh’s. Materials like Frits, feldspar, quartz, traditional bodies, glass & paints can be ground easily within a short grinding period.

Steatite Grinding Media & lining Bricks are resistance to all acids and alkalis. (Except Hydrofluoric Acid).This Grinding Media and Lining Bricks are fully Vitrified, having water absorption less than 0.05% and can be used in vibrating & rotary devices for surfaces working of metal, ceramics, plates & wood.

| Chemical Analysis: | |

| Al2O3 | ≤ 7.00 % |

| SiO2 | 61.50 % |

| Fe2O3 | 0.50 % |

| MgO | ≤ 27.00 % |

| BaO | 3.20 % |

| Na2O | 0.10 % |

| CaO | 0.50 % |

| 1. | Bulk Density | 2.65 to 2.75 |

| 2. | Water Absorption | 0 to 0.05 |

| 3. | Hardness on Moh’s Scale | 7 to 8 |

| 4. | Wear Resistance | Very Less |

| 5. | Specific Gravity | 2.8 to 2.9 |

| 6. | Colour | Off White - White |

| 7. | Apparent Porosity | 0.1 to 0 |

| Sizes of STEATITE Balls | |||||||||||

| Diameter (Ø) (mm) | Ø 6 |

Ø 8

|

Ø 10 |

Ø 12 |

Ø 15 |

Ø 19 |

Ø 25 |

Ø 30 |

Ø 40 |

Ø 50 |

Ø 60 |

© Copyright 2011 AInternational | All Rights Reserved.